HP Indigo 35K Digital Press

The future unfolds

Profit from high-growth business with a high-performance press for short runs of folding cartons.

Optimize production efficiency by shifting to a digital mindset

Produce dozens of jobs per day and up to 1 million B2 sheets per month, taking advantage of new tools to increase printing time by up to 40%. print time by up to 40%.

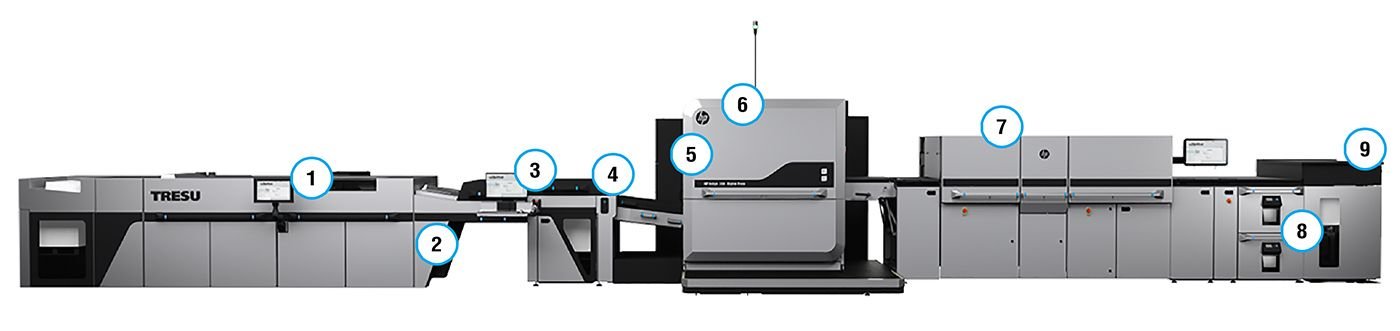

1.- Tresu iCoat II

Dual UV/WB flexo coater designed for use in high flexo environments and optimized to work in-line with the Indigo 35K press; now supports high precision varnish for embellishment.

2.- In-line liner adapter

Complete press-recoater coupling, with new in-line coater adapter and SW synchronization of units.

3.- Spot Master

Reduce job setup with faster color turnaround times by using Spot Master, an automatic color alignment process.

4.- Parallel Color Calibration Station

Align color and maintain consistency without interrupting production in parallel to printing.

5.- 7 ink stations

7 interchangeable ink stations, compatible with CMAN, OVG and spot colors (for 97% of the Pantone gamut), as well as superior white and invisible yellow, among others.

6.- HD Imaging System (optional)

Create even smoother color tones, a larger number of smaller images and sharper micro texts with the HD imaging system.

1.- In-line priming unit

Expand your offering of ready-to-use paperboard, from cardboard to high-end color substrates and metallized and synthetic substrates.

2.- Pallet feeder and 2 drawers

Easily transition from job to job with drawers, pallet feeder and proofing capabilities during printing.

3.- Format B2

Meet short turnaround times with a B2 format that is perfect for short runs and saves half the cost and conversion waste compared to B1 format.